|

|

Here are dimensions for most of the o-rings (quad

rings) you would require

My thanks to Derek for this info.

The original Norton Commando rev counter gear does

not have a groove in the top. If you buy a new

gear, or have the later type, you need the smaller

o-ring # 06.5203.

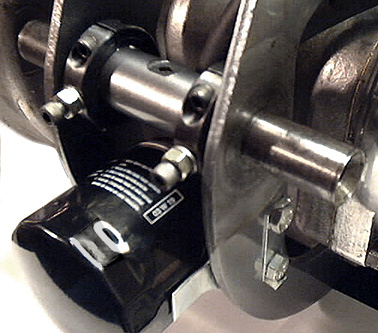

Pilot hole on the right, final hole on the left. Assembled with grease, thread locker, and some Permatex #2.

Final installation. ...well almost final. The heads of the adjustment screws hit the swing arm brace, so I turned the heads down, shortened the screws and took the locknuts down to half thickness.  Heinz's instructions specify drilling @ 8 o'clock, this I did, and it is correct.. but it was with the engine on the bench as pictured. When the cradle is installed in the frame the front end sits lower than on a bench, so 8 o'clock becomes 9 o'clock, and 9 o'clock is a problem! So, when installing: on a bench = 7 o'clock, cradle in frame = drill at 8 o'clock. Better yet, trim the adjusting screws down so you never have to worry about hitting the swing arm. You can order a pair from Heinz Kegler himself.

|